- ZK

- Guangdong, China

- 7-15 días

Inversor de bomba solar MPPT de alto rendimiento ZK300, desde 7,5KW a 16KW, 220V, 380.

Funciona bien con todo tipo de motores de CA, incluidos AM/IM, PMSM y motores de alta frecuencia y alta velocidad.

Inversores solares, bomba solar, inversor, sistema de inversión solar, inversor de bombeo solar, bomba de agua, inversor

1/3 fase 220V TRIFÁSICO 380/440VInversor de bomba solar con variador de frecuencia MPPT alimentado por energía solar

Descripción del Producto

Inversores solares, bombas solares, inversores solares, sistemas de bombeo solar, inversores, bombas de agua, bombas de agua solares, inversores VFD, inversores solares, inversores VFD

Características del inversor de bomba solar ZK300

● Nombre del producto: Inversor de bomba solar MPPT VFD

● Tipo de producto: Inversor de bomba solar híbrido MPPT

● Apoyo Inversor de bomba solar monofásico/trifásico

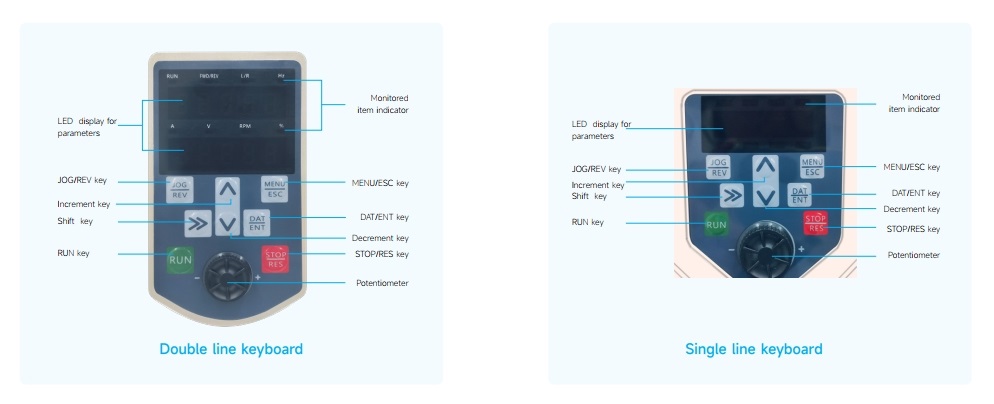

● Teclado: LED/LCD

● Rango de frecuencia de salida: Tipo G: 0 ~ 3000 Hz

● Rango de voltaje de CC: 250-900 VCC

● Fácil de usar, no es necesario configurar ningún parámetro, se puede iniciar automáticamente después del encendido.

● Múltiples medidas de protección que pueden prolongar eficazmente la vida útil del producto.

● Algoritmo MPPT avanzado que garantiza que la eficiencia de seguimiento de la energía solar pueda alcanzar el 99 %.

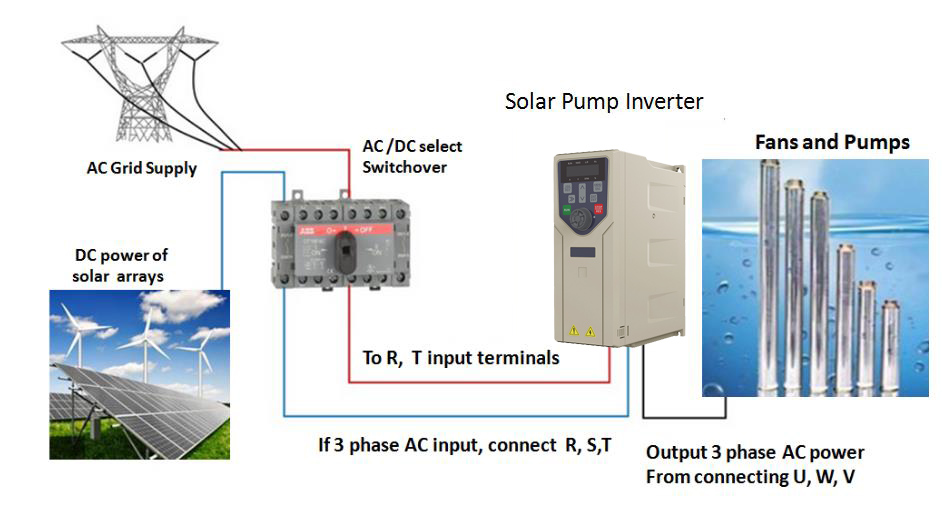

● Conmutación automática de la entrada de CC fotovoltaica y la entrada de CA de la red

● Admite monitoreo remoto GPRS, se puede ver en computadora y teléfono móvil (opcional)

※ Estructura compacta, estable y confiable.

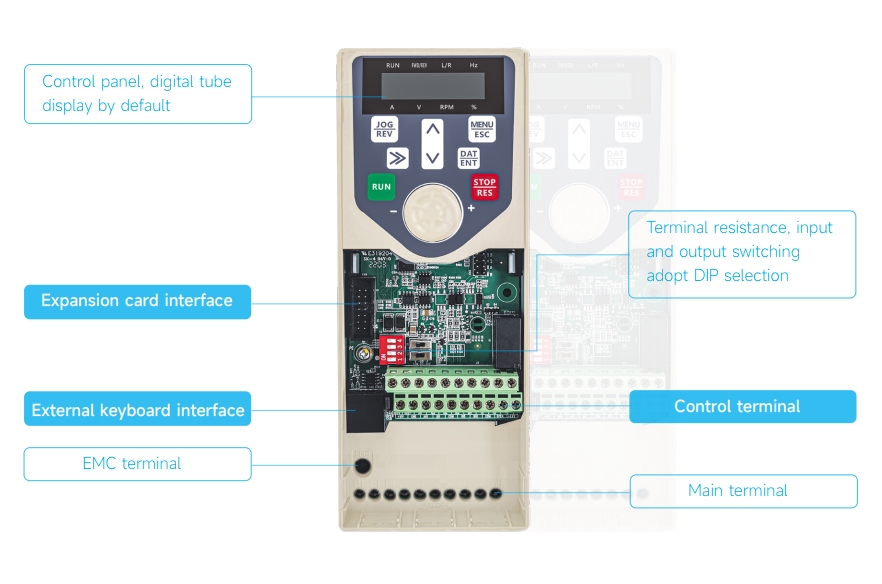

※ Operación del teclado

Diseño avanzado de disipación de calor. Un teclado de panel de nuevo diseño con una operatividad superior. El teclado integrado y el teclado externo admiten una pantalla de doble línea (el control se puede seleccionar mediante los parámetros del variador, ya sea el teclado integrado o el externo).

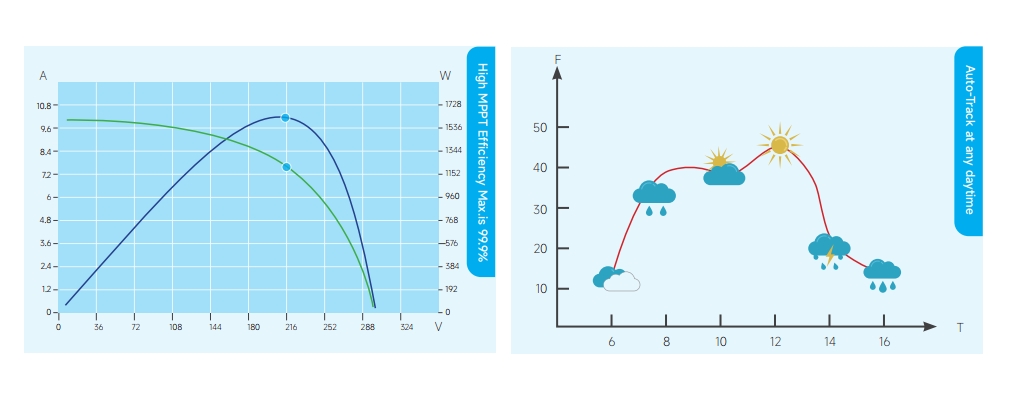

※ Tecnología MPPT avanzada

Al ajustar continuamente el voltaje y la corriente de salida del inversor para que coincidan con el punto de máxima potencia en la intensidad de luz actual, la eficiencia máxima de MPPT puede alcanzar el 99,9%.

Especificaciones técnicas del inversor de bomba solar ZK300

| Elementos | Presupuesto | |

|---|---|---|

Entrada de potencia | Voltaje | 1T: 90 VCC a 400 VCC S/2T: 150 VCC a 450 VCC 4T: 250 VCC a 800 VCC/350 VCC-800 VCC |

| Frecuencia | 50 Hz/60 Hz, tolerancia ±5 % | |

Rango de voltaje | Fluctuación continua de voltaje ±15% fluctuación corta -15%~+15% | |

| Tasa de desequilibrio de voltaje <3% | ||

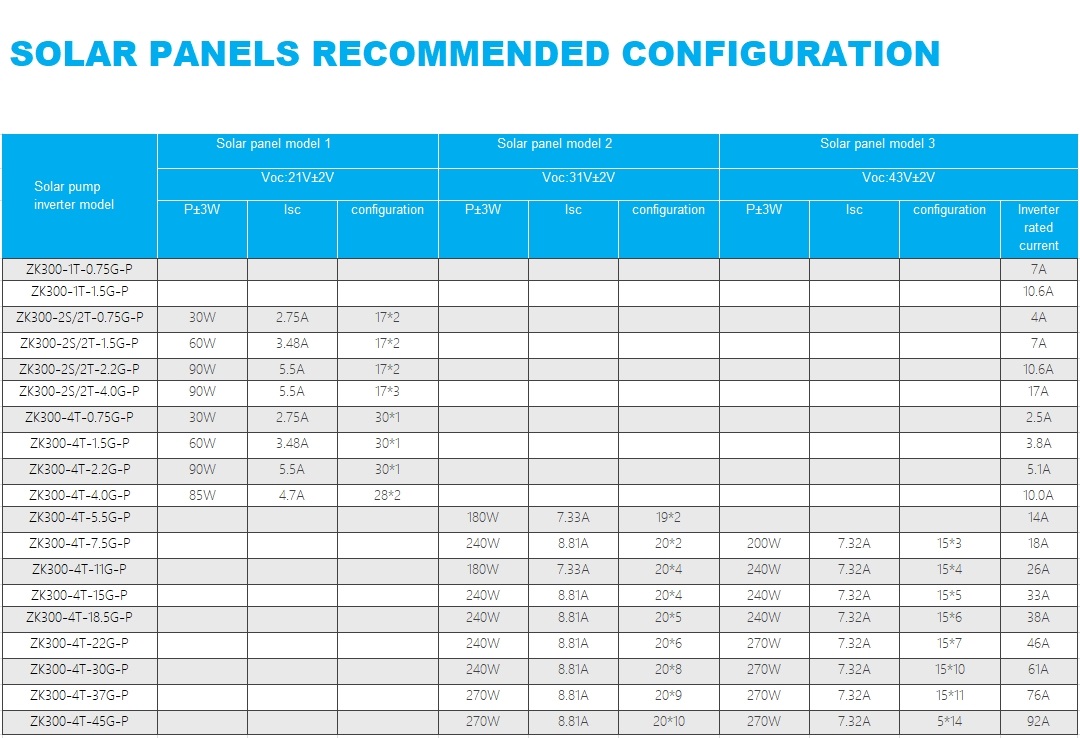

Rango total de COV (V) de los paneles recomendados | Tipo 1T: 175-380 VCC Tipo 2S/2T: 360-430 VCC Tipo 4T: 620-750 VCC | |

| Potencia de salida | Tipo de motor adaptativo | motor asíncrono trifásico Motor síncrono de imán permanente |

| Voltaje de salida (V) | Trifásico: 0% ~ voltaje de entrada nominal, error < ±3% | |

Frecuencia de salida (Hz) | 0,00 % ~ 599,00 Hz; Unidad: 0,01 Hz | |

| Capacidad de sobrecarga | 150 % de corriente nominal/1 min 180 % de corriente nominal/10 s 200 % de corriente nominal/0,5 s | |

| Funciones básicas | Tiempo de ACC/DEC | 0,0 ~ 30000 s |

| Frecuencia de conmutación | 0,5 kHz ~ 16 kHz | |

| Ajuste de frecuencia | Configuración digital + panel de control, Comunicación, Configuración analógica, Configuración de pulsos de terminal | |

Motor métodos de puesta en marcha | Comenzó desde la frecuencia de inicio, inicio del seguimiento de velocidad | |

| Métodos de parada del motor | Rampa para detenerse, Parada libre | |

| Función de protección | Protección de la bomba solar función | Funcionamiento en seco, baja frecuencia, baja potencia, inactividad, agua llena, protección contra sobrecorriente de la bomba |

Protección básica función | Protección de la unidad inversora, Sobrecorriente durante la aceleración, Sobrecorriente durante la desaceleración, Sobrecorriente en velocidad constante, Sobretensión durante la aceleración, Sobretensión durante la desaceleración, Sobretensión a velocidad constante Velocidad, Subtensión, Pérdida de fase de entrada de potencia, Pérdida de fase de salida de potencia, Sobrecarga del inversor, Sobrecarga del motor, Fallo de detección de corriente, la temperatura del inversor excede el límite, la carga pasa a 0, desviación de velocidad demasiado grande, Cortocircuito a tierra, Falla de equipo externo, Falla de límite de corriente rápida, Falla de comunicación, Maestro-esclavo Desconexión de la comunicación de control, falla de lectura y escritura de EEPROM, pérdida de retroalimentación PID durante la ejecución, almacenamiento de datos Fallo, Fallo de la fuente de alimentación de control, Fallo de conmutación del motor durante el funcionamiento, Tiempo de funcionamiento acumulado alcanzado | |

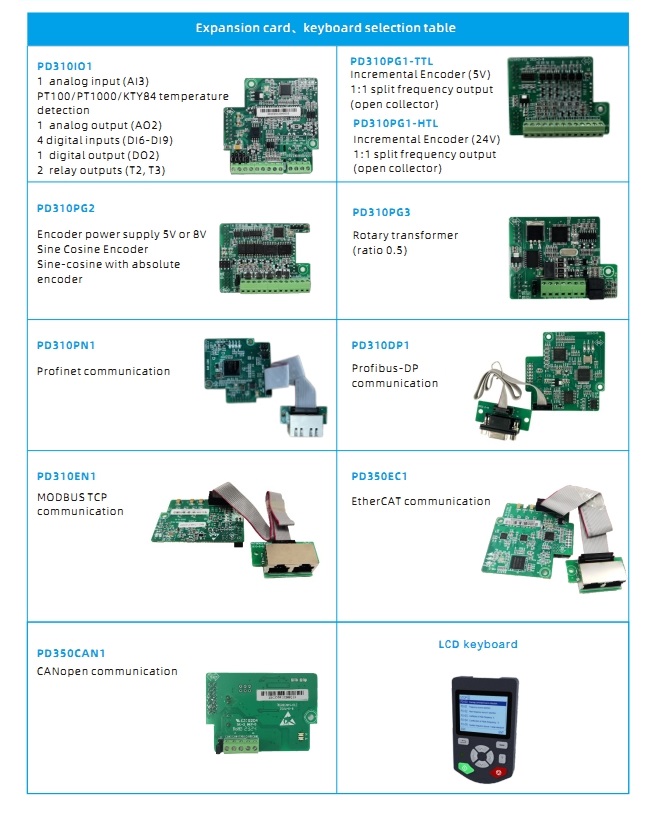

Comunicación red | Admite protocolo 485/Modbus, protocolo Profibus-DP, protocolo CANopen, protocolo Profinet, protocolo EtherCAT, Protocolo Modbus TCP y protocolo CAN personalizado | |

| Ambiente | Lugar de operación | En interiores, sin luz solar directa, libre de polvo, gases corrosivos, gases inflamables, neblina de aceite, vapor de agua, gotas de agua o sal, etc. |

| Altitud | 0~2000 m. Reducción del 1 % por cada 100 m cuando la altitud supera los 1000 metros. | |

Ambiente temperatura | -10℃~ 50℃, la corriente de salida nominal debe reducirse un 1% por cada 1℃ cuando la temperatura ambiente sea de 40℃~ 50℃ | |

| Humedad relativa | 0~95%, sin condensación | |

| Vibración | Menos de 5,9 m/s² (0,6 g) | |

Almacenamiento temperatura | -20℃~+60℃ | |

Otros | Grado de protección IP | IP20 |

| Método de enfriamiento | Refrigeración por aire forzado | |

CONLista de accesorios del inversor de bomba solar K300

SAplicaciones de inversores de bombeo solarsistema

※ Aplicación del inversor de bomba de agua solar

- El inversor de bomba de agua solar se utiliza ampliamente en riego agrícola, suministro de agua en áreas remotas y circulación de agua industrial.

- Utiliza energía solar para impulsar bombas de agua, lograr conservación de energía y reducción de emisiones y reducir costos operativos.

- En áreas con suficiente luz solar, este inversor se convierte en una opción ideal para reemplazar la energía tradicional y promover la utilización ecológica y sostenible de los recursos hídricos.

Bomba de agua solar VFD, inversor solar VFD, bomba solar híbrida, híbridos, inversor solar, agua, variador de frecuencia, solFabricación de inversores para controladores de bombas, controladores de motores de CA